新闻详情

News detail

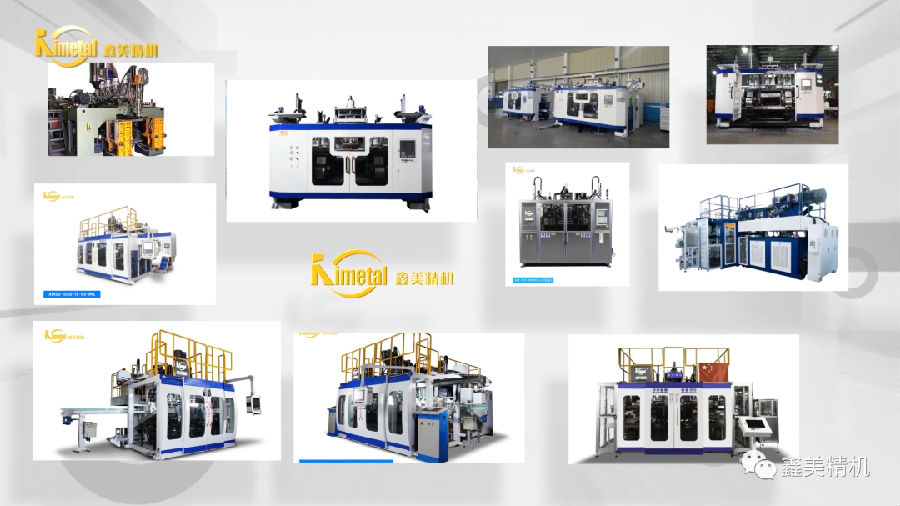

- Hollow molding machine

- Multi-layer blow molding machine

- PU air cushion machine

- Special blow molding

- Blow molding machine special accessories

- Online automatic weighing machine

Xinmei launches 4L in-mold labeling integrated machine for high-speed stacking barrels, creating with heart and moving forward together for the future!

With the advent of the post-epidemic era, 10-30L stacking barrels and 1-4L oil bottles are increasingly widely used worldwide. In response to the growing market demand, Xinmei Precision Machinery has devoted its efforts to create and launch a number of new models in midsummer. The machine has obtained a number of national technical patents and has been put into normal production. The design and research team closely follows the actual production, solves the bottlenecks and pain points that restrict on-site production, and realizes a simple and efficient design concept. Let us learn about their abilities.

A, XMS-105S-SL-VS (Special machine for stacking barrels)

The 20L stacking barrel machine adopts continuous extrusion and rapid horizontal mold blowing movement, which can realize one-button rapid bottle output on the human-machine interface; multi-station rear cooling auxiliary shaping greatly improves production efficiency, and the machine realizes the connection of finished product conveying and water outlet separation conveying. There is an operating platform above the front frame for easy maintenance, and it can be connected to online weighing, leak detection, AI detection and other rear-stage automated process connections. It adopts a multi-layer plus visual line co-extrusion structure to meet the environmental protection PCR composite co-extrusion concept, and achieves a low-carbon, environmentally friendly, stable and efficient, and automated closed-loop production innovative production model.

XMS-105S-SL-VS (Special machine for stacking barrels)Video Introduction

B,XMSS-105D-TL-VS-IML (special machine for lubricating oil pot)

This machine is a special machine for oil cans. The locking platen is based on the European strong crankshaft locking. The mechanical distribution points of the platen are strengthened to make the force more uniform and the locking force greater! The frame recycling design of the water outlet scraps in the mold frame makes the production cleaner and safer. It is equipped with an integrated in-mold labeling machine, and the whole machine is more compact and efficient. The multi-layer co-extrusion structure design and the die head meet the design requirements of fast color change and stable weight. While meeting the special requirements of environmental protection PCR, the second mold is higher than the ordinary 3-5 seconds. In order to improve the efficiency of mold change, the machine is equipped with a mold change crane (disassembly-free) to effectively reduce the mold change time.

XMSS-105D-TL-VS-IML (machineOiler special machine)Video Introduction

Guangdong Xinmei Precision Machinery Co., Ltd.

Address: No. 253, Dongzheng Road, Changping Town, Dongguan City, Guangdong Province

Tel:(0769) 89385095 89385096

Email: xm-jj@foxmail.com

Website: www.a-mt.cn