新闻详情

News detail

- Hollow molding machine

- Multi-layer blow molding machine

- PU air cushion machine

- Special blow molding

- Blow molding machine special accessories

- Online automatic weighing machine

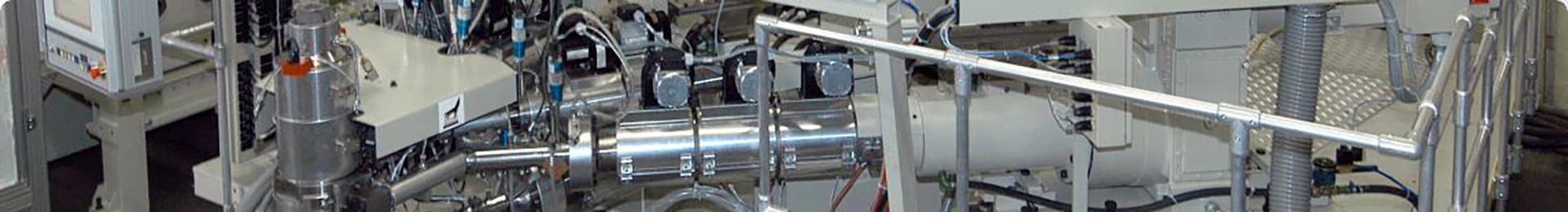

Technical overview of automatic hollow forming machine

Technical introduction of plastic multi-layer co-extrusion hollow molding machine

Multi-layer coextrusionAutomatic hollow forming machineThe molding machine is very promisingAutomatic hollow forming machineForming Machine. Multi-layer blow molded hollow products with high barrier properties will inevitably account for an increasing proportion in the field of hollow products. Multi-layer blow molding products are not only developing rapidly in the food packaging industry, but also in the packaging of chemicals, cosmetics, medicine and health and other industries.

Multi-layer coextrusionAutomatic hollow forming machineExtrusion blow molding machine in our countryAutomatic hollow forming machineto makeIt is a weak link in the field of model machines. The development of multi-layer co-extrusion hollow products promotes multi-layer co-extrusionAutomatic hollow forming machineThe development of molding machines. InternationalIn recent years, multi-layer co-extrusionAutomatic hollow forming machineThe speed of the molding machine development is very fast, and the technology progress is also very fast. There are also some varieties launched in China, for example, developed by Hengyang Huayi Machinery Rubber and Plastic Machinery Co., Ltd.HYB-75DThree-layer co-extrusion double-station in-mold labeling hollow molding machine, using four-die head double-station, equipped with precise integrationPIDTemperature control system, real-time detection of the extrusion pressure of each screw, automatic flash removal, and accurate Siemens full computer control to reduce the thickness of the middle and inner layers without affecting the quality of the product's permeability (0.03-0.05mm),Filled up the domestic gap. Shaanxi Qinchuan Plastic Machinery Factory can produce six layers500LCoextrusionAutomatic hollow forming machineThe molding machine has reached the level of similar machines in Germany.

Technical Overview of Large-scale Plastic Injection Blow Molding Machine

Injection blow largeAutomatic hollow forming machineThe molding machine is extruding and blowing largeAutomatic hollow forming machineDeveloped on the basis of the molding machine, suitable for molding single-layer largeAutomatic hollow forming machineProducts.

Injection blow largeAutomatic hollow forming machineThe molding machine combines the injection plasticizing mechanism of the injection molding machine with the extrusion blowAutomatic hollow forming machineto makeA comprehensive model where the blow molding and clamping mechanism of the molding machine are combined with each otherAutomatic hollow forming machineThe molding machine absorbs and exerts the respective advantages of the two machines to achieve high parison weight repeatability, high plasticizing capacity, short color change and material change time, and high strength in the melt fusion seam area.

Squeeze largeAutomatic hollow forming machineThe molding machine generally uses a storage head, which has a complex internal structure and many parts, so it isThe characteristics of the material-type head itself inevitably have disadvantages such as long color and material change time and inaccurate measurement accuracy. Injection blow largeAutomatic hollow forming machineExtrusion blow of the head of the forming machineAutomatic hollow forming machineThe two functions of the storage head of the molding machine and the injection and extrusion parison are separated and completed by the injection plasticizing mechanism. In this way, the head has the advantages of continuous head easy color and material change, and at the same time , Simplifies the structure of the machine head, coupled with a reasonable runner design, fundamentally solves the problem of squeezing and blowingAutomatic hollow forming machineThe storage type head of the molding machine has the defect of long color change and material change, and it does not affect the installation of the parison wall thickness control servo system.